Overview

Welcome to instant quote, our convenient self-quoting tool for CNC machining and digital printing services on Polycase enclosures. With over 30 years of experience, we can handle all your project’s needs, from complex cutouts to full color printing, we will save you time and money on your end product.

CNC Machining

From basic cutouts for cables, or buttons, to advanced hole types and more- we save you the hassle of sending your enclosure to a third party by fulfilling your machining needs before your enclosure leaves our door, all at a cost-effective price.

Digital Printing

Adhesive labels can take hours to place, end up crooked, and never last long. Our digital printing services eliminate all of that for a long-term solution printed directly onto the enclosure, adding a level of professionalism that labels just can’t.

Quotes can be completed in 4 easy steps:

1.) Select your Polycase Product

2.) Choose your CNC machining requirements

3.) Choose your digital printing requirements

4.) Save and view your Instant Quote

From here you can attach drawings to your quote and add it to your cart for convenient online ordering.

For an in-depth walkthrough of our Instant Quote tool, visit the “Tutorial” tab.

Tutorial

- STEP 1

Product

Select Quote Type

Start your quote by selecting if the quote is for a new customized enclosure or for a revision to an existing customized enclosure. A revision means we have previously produced customized enclosures for you and we are now revising the machining, printing or both for that specific project/custom part. When a revision is ordered the previous version is made obsolete and no longer orderable.

Select Product Options

Next, select the product series and part number of the enclosure to be quoted. Once selected, any available options for that part will be presented for you to make selections from. Once your options are selected you can click "continue" to move on to the next step

At any point in the process you can restart your quote by clicking "restart" or save your progress by clicking "save for later".

- STEP 2

Machining

Select Machining Options

The next step is selecting your machining requirements. Machining is based on the number of surfaces being machined, and the total number of features. Make selections based on the options presented to you. A drawing indicating the area(s) available to machine is displayed for reference. Tool tips are available at each step to guide you through the process.

Machining Requirements

We do not need to know the size, location or details of machining for the quoting process. Machining information/drawings are not required until you are ready to order your customized project.

If you do not require machining, you can simply continue on to printing.

- STEP 3

Printing

Select Printing Options

The last step is selecting your printing/graphics requirements. Printing is based on the number of surfaces being printed, and number of colors per surface. Make selections based on the options presented. A drawing indicating the area(s) available to print is displayed for reference. Tool tips are available at each step to guide you through the process.

Printing Requirements

We do not need to know the size, location or details of printing for the quoting process. Drawings/graphics are not required until you are ready to order your customized project

If you do not require printing, you can proceed to the summary page.

FAQs

(4) CNC Machining

Yes, we can machine down the height, or remove, the mounting bosses. Because they are only ¼” tall, often they do not interfere with the desired application, but if they do, they can be machined out or made shorter. Additionally, some of our enclosures are available with or without the bosses.

Because the enclosure covers are created to fit tightly to the enclosure, once the base is machined down the covers will no longer fit. So this is only recommended for potting boxes or applications that do not require a cover.

We can machine any size or shape holes that you needed, on any surface of the enclosure. Polycase design engineers are happy to help you with the design if you need assistance. Based on the board and connectors you use, together we will be able to determine the best locations and sizes of holes that would work for your product.

Polycase can machine virtually any size or shape opening that you may require, however all drawings will be reviewed by Polycase to ensure manufacturability. All square and rectangular cutouts will typically have a minimum corner radius of 0.031" and tolerance on machined features will typically be +/-0.005". These may increase depending on enclosure selected and feature machined. For components we typically recommend sizing your cutouts to be .040" larger than the component (or .020" for round cutouts). Occasionally, certain features may not be able to be machined or will require a non-standard approach which could increase the machining price. This would be determined when the order is placed. Contact Polycase Technical Support if you have specific questions regarding a machined feature.

(5) Digital Printing

Digital printing involves the spraying of ink directly onto the enclosure and then curing with UV light. The printer uses software to manage the image, controlling when the printer releases tiny droplets of ink directly onto the enclosure’s surface. The ink is applied in a specific sequence and pattern that allows the digital image to be accurately recreated. Digital printers have the capacity to print a variety of colors and gradients, but there are some limitations (like neon colors). When digital printing, we utilize specially designed fixtures to ensure accuracy. Because of this, if the enclosure is too large or has a feature that will compromise the print or equipment, we will likely resort to pad printing.

Pad printing uses a plate to transfer ink from the pad to the enclosure. This method only allows one color to be printed at a time, along with only being able to do a single enclosure at a time. The quality between digital printing and pad printing oftentimes does not vary.

The ink used in the digital printing process is UV cured. The adhesion / scratch resistance of the ink on the plastic is excellent. The ink cannot be scratched off of the plastic without mechanically scratching into the plastic itself. Internal cross hatch cut and tape testing resulting in no ink being pulled up after testing was completed.

Furthermore, after internal testing according to UL Standard UL 61010-1 (Electrical Equipment for Measurement, Control, and Laboratory Use, Section 5.3, Durability of Markings), there was no observable degradation in legibility, smearing or fading of the printing after performing the test.

The ink used in our printing process is acrylic based; UV cured, and is an ink system that is used for labels. It's not labeled as UV resistant because it reacts with, and is cured by UV light. However, the ink can be exposed to UV rays. The ink is commonly used in the sign and banner industries which endure heavy UV exposure. As with any ink, the color will fade over time. You may start to see fading in 2-3 years for typical outdoor applications and 3-5 years for typical indoor applications.

Vector based artwork is required. This includes, but is not limited to, Adobe Illustrator, Corel Draw, and .pdf or .eps files.

(ACCEPTABLE ARTWORK FILES CHART/ PDF HERE)

Colors will be printed per your electronic artwork file. Artwork should be designed for the CMYK color space. If a PMS color value is requested, the CMYK equivalent will be printed. There may be a color shift in the process depending on the specific spot color. Black, red, and white are the available colors for keypad printing.

When printing is ordered, graphic file(s) with fonts converted to outlines or curves is suggested. If not converted, any fonts that are used should be sent along with the graphic file(s). If a font is not provided Polycase will use Arial.

Polycase offers full-color digital printing (also referred to as a 4-color process or CMYK) on most surfaces. It can be used for simple text, gradients, blended colors, color transitions, or photo-quality images. Vector based artwork (designed for the CMYK color space) is required for printing. In the unlikely event a surface is not eligible for full-color digital printing, Polycase can pad print. During approval process, Polycase will advise if pad printing will be performed.

(8) Custom Ordering

Learn about what happens after you place your custom order by watching our 60-second clip.

Our standard lead time for customized enclosures is 3 weeks, but please note that this may be subject to change depending on the availability of imported products. We also offer 1 and 2 week production expedite options. Expedite pricing can be found on your quote.

Orders can be placed right from your quote summary page. Drawings and files can be submitted at the time of order, or after the order is placed. But please note your lead time cannot begin until all drawing and/or artwork files are received for the order.

Quotes are saved in your account they can be accessed through the "My Quotes & Custom Parts" link in the "My Account" section after logging in

Yes, a quote can be edited at any time prior to ordering. Once ordered, it is no longer editable.

Polycase values and protects our customers’ privacy. Part of this is protecting our customers’ custom products. In order to purchase a custom product on behalf of your customer, have your customer provide you with the Polycase custom part number, quote number or Polycase drawings. Or your customer can contact us directly to let us know who will be purchasing the product going forward, and to confirm we have their permission to sell this product.

We offer 1 and 2 week production expedite options. Expedite pricing can be found on your quote. (Standard lead time is 3 weeks.)

Polycase production drawings are not created until an order is placed. Once an order is placed, production drawings are created and sent to you for review and approval prior to production.

(6) Instant Quote

Almost all stock enclosures found on the website can be customized and quoted online. You can also quote revisions to your existing Polycase customized enclosures.

The only enclosures we do not offer customization services on are the SA Series stainless steel enclosures, certain sizes of the SB Series steel enclosures and certain sizes of the WQ series enclosures. If the enclosure does not show up in Instant Quote, then we do not customize that specific size.

What is the difference between a new customized enclosure and a revision to an existing custom part?

A revision indicates you have an existing customized part with Polycase (part #'s start J-, JG- or G-) and you need to modify the machining, printing or both for a next generation or new version of the old enclosure. When revising an existing customized enclosure, the previous version is marked obsolete and it can no longer be ordered.

A new customized enclosure is a brand new project that has not been ordered before.

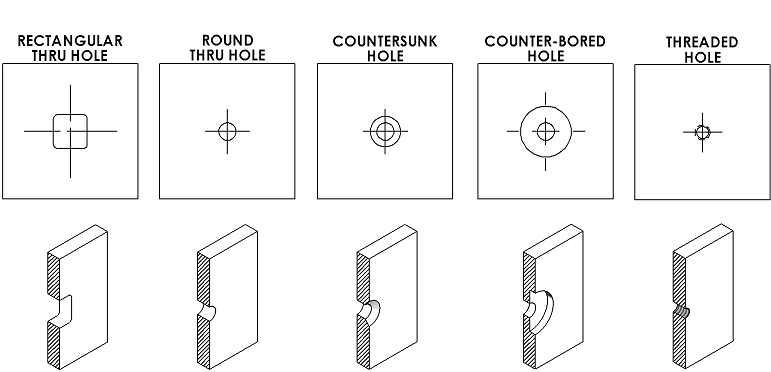

A feature consists of any size or shape through-holes, countersinks, counter-bores, recesses, bevels, taps, screw tower removals, mounting boss removals, or interior wall thinning. For example, a round hole would be 1 feature. A round hole with countersink would be 2 features (1 feature for the through hole, 1 feature for adding the countersink). Counterbored holes and threaded holes would also be considered 2 features. Examples of common features are shown below. Non-standard features can be quoted by contacting Polycase Technical Support.

These are non-recurring charges on your first order for a new or revised project to set-up and create your new customized part (i.e. create custom part numbers, engineering drawings, CNC programs, digital artwork files and printing plates for the enclosures). The charges are applied to first time new and revised orders only.

Quotes are saved in your account they can be accessed through the "My Quotes & Custom Parts" link in the "My Account" section after logging in.

Yes, a quote can be edited at any time prior to ordering. Once ordered, it is no longer editable.

Contact Us

Need help?

We’re available 8:00-5:00

EST Monday-Friday